Tariff Mining Mill To Grind

.jpg)

铁矿石生产线设备的投资价格与生产成本 知乎

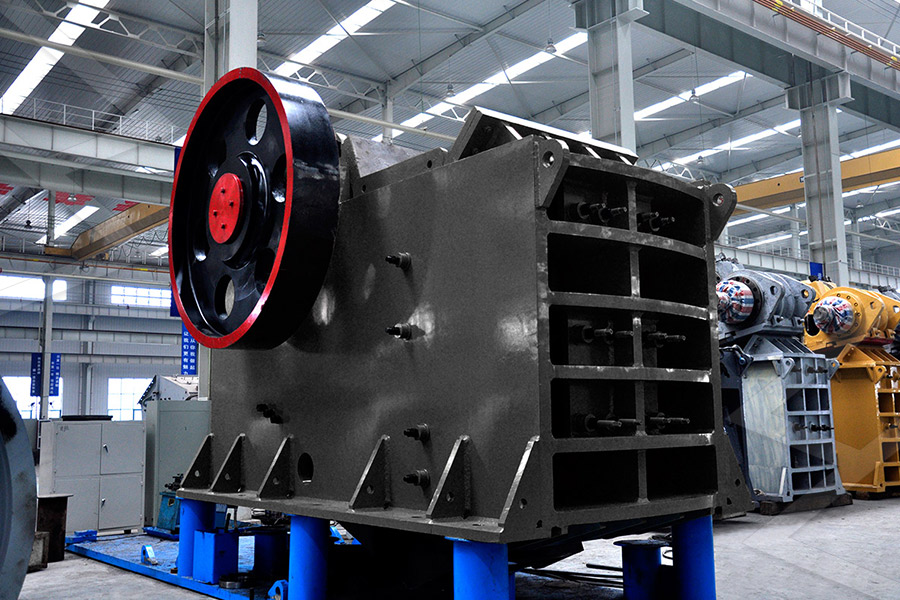

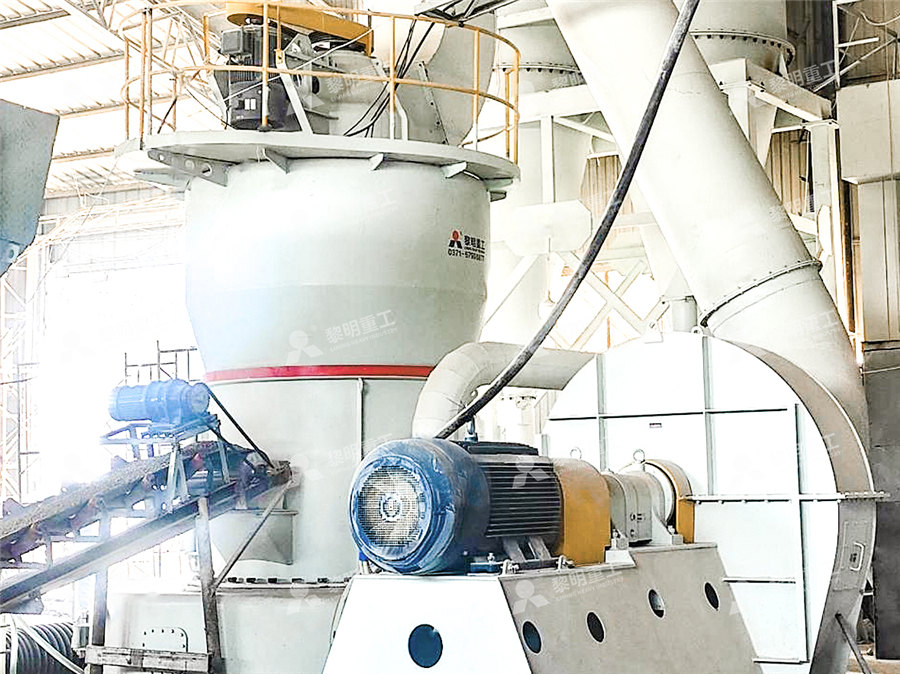

2021年12月1日 — 铁矿石生产线工艺流程是指开采的矿石经过各个作业后得到符合冶炼要求的精矿的生产过程。 选矿工艺流程主要包括:矿石破碎与筛分、球磨机磨矿与分级机分级、矿物分选 (重选、浮选与磁选等)、矿物质脱水 (浓缩、过滤、干燥等)。 铁矿石生产线设备 2014年2月1日 — Coarse particle flotation may reduce the impact of mill costs An understanding of the breakdown of mine costs is an important tool for researchers and Mine operating costs and the potential impacts of energy and 2021年1月24日 — 日本铜冶炼企业上世纪70年代开始普及闪速工艺及自主研发的三菱法工业化生产后,铜冶炼能力迅速提升,日本成为世界最大的铜精矿进口国,当时BHP与日本的 一文看懂铜精矿加工费的基准价冶炼2014年2月1日 — This paper provides a breakdown of operating costs in 63 mines by dividing them into three main categories: mining, milling, and general and administrative (G A) Mine operating costs and the potential impacts of energy and

2020年最新版!主要矿产一般工业要求汇编

2021年9月15日 — 冶金用锰矿石一般工业指标 注1:灰质氧化矿石(脉石以方解石为主,碱度大于或等于08,烧失量达18%以上)的评价,可采用碳酸锰矿石的工业指标。2023年7月13日 — The Outotec HIGmill® is an advanced and energyefficient fine and ultrafine grinding solution that relies on proven technology The mill takes advantage of OUTOTEC HIGMILL – ENERGYEFFICIENT HIGH 2023年9月21日 — INTRODUCTION Vertical stirred milling is a wellrecognized technology for the secondary, regrind and fine grinding applications and are increasingly replacing RECENT DEVELOPMENTS IN COARSE GRINDING USING 4 天之前 — This paper provides a breakdown of operating costs in 63 mines by dividing them into three main categories: mining, milling, and general and administrative (G A) costs Mine operating costs and the potential impacts of energy

.jpg)

Tariff Mining Mill To Grind technesrl

AG/SAG mills are normally used to grind runoffmine ore or primary crusher product Wet grinding in an AG/SAG mill is accomplished in a slurry of 50 to 80 percent solids 2D and 2024年9月25日 — AgnicoEagle Goldex Division, Mine Canadian Malartic, and New Gold New Afton Mine participates in the study by providing operating data for 3 semi Breaking Down Energy Consumption in Industry Grinding MillsHIGmill high intensity grinding mill is an advanced and energyefficient fine and ultrafine grinding solution that relies on proven technology Mining Supporting your operations, from plant design expertise to equipment, HIGmill high intensity grinding mill Metso2013年7月31日 — Reference: Wills, BA, 1988, “A Rapid Method for Measurement of Fineness of Grind”, Minerals Engineering, Vol1, No 1, pp 8184 Here is an Excel produced Table of a 32 SG rock on which you Quick Grind Check How to Quickly Estimate

Understanding the operation of grinding mills in the mining

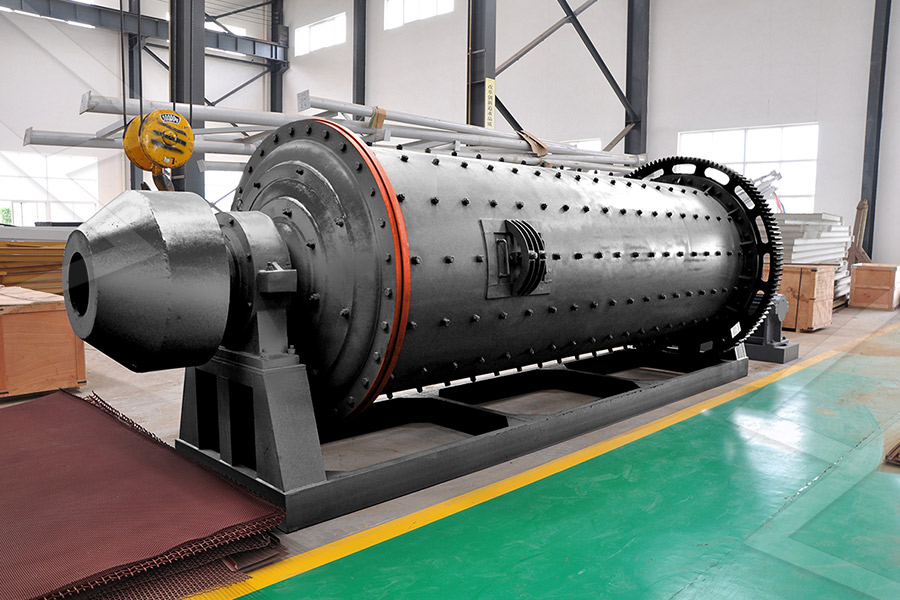

2024年9月22日 — Grinding mills are crucial equipment in the mining and mineral processing industry, used primarily for the reduction of ore and mineral particles The proper functioning of grinding mills is vital for the efficiency of the overall processi The ore is fed into the mill and as the cylinder rotates, the balls crush and grind the ore, causing 2022年9月1日 — Moreover, in most cases, waste rock is harder and, consequently, more difficult to grind than the ore which is often found in the weaker areas of the rock The harder the rock, the longer the grinding time and the lower the mill throughput Further, hard rock results in overgrinding the ore and higher energy consumption Efficient handling Towards waterless operations from mine to mill ScienceDirect2017年10月26日 — a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this factor into account As well, mills with different length to diameter ratios for a given power rating will yield different material Factors Affecting Ball Mill Grinding Efficiency 911Metallurgist6 天之前 — DOVE Ball Mills are highly efficient grinding mills designed to grind and blend bulk material ranging from soft, fibrous to hard and brittle material DOVE Ball mill, also known as Grinding mill, Mining mill, Pebble mill, Ball Pebble mill, is an important machinery in the mining and various other industries, which would require grinding Ball Mill Ball Mills Wet Dry Grinding DOVE

Grind Calibration Curve Laboratory Test 911Metallurgist

2015年8月6日 — Before doing multiple laboratory flotation bench tests in which you need P80 grind controlled or predicted, you need to build a Grind Calibration curve following this short procedure You will consistently add sufficient water to the mill to achieve a pulp density of 67% solids (Example: 1 kg solids + 05 kg water or 2 kg solids + 1 kg water)We also produce a range of mill liner bolts and specialised fasteners to the highest technical specifications Molycop is dedicated to providing the latest in technological advances to our customers Our consumable products coupled with our specialised range of milling instrumentation and real time analytics will deliver improved outcomes for Milling MolycopGrinding Mill worth $7,936,222 under Sub Chapter 8479 have been imported; Average import price for grinding mill under Sub Chapter 8479 was $12237 Please use filters at the bottom of the page to view and select unit type [FOC] GRIND LID [SPARE PARTS TO BE USED IN DEVELOPMENT OFHUMMER MILL MACHINERY][SAMPLE] Angola: Grinding Mill Imports Under Sub Chapter 8479 ZaubaGrinding Mills: Ball Mill Rod Mill Design PartsCommon types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed herePhotographs of a glass ended laboratory Grinding Mills 911Metallurgist

.jpg)

Mining Ball MillHongji Mining Machinery

2024年6月5日 — Ball mill, also known as mining ball grinding machine, is one of the commonly used equipment in mining production It is mainly used to crush and grind ore It is mainly used to crush and grind ore The mining 2017年6月2日 — Heavy mining, quarried materials, sand gravel, recycling: Table Source: Wikipedia (Crushers) Buhrstone and disk attrition mills grind media between a horizontal or vertical rotating grooved stone or How it Works: Crushers, Grinding Mills and The ability to finely grind materials and control the grinding process makes ball mills crucial equipment in cement manufacturing Mining and Ore Processing: Ball mills are used for grinding ores and minerals, enabling the extraction of valuable metals They are widely employed in both wet and dry grinding processes for the comminution of Ball Mill Grinding Machines: Working Principle, Types, Parts 2024年1月2日 — China’s duties for mostfavored nations, including Russia, Mongolia, South Africa and the US, have returned to a rate of 6% on coal for power and heating and 3% on coking coal used by steel millsChina restores coal tariffs in threat to Russian exporters

.jpg)

The Ultimate Guide to Ball Mills Miningpedia

2019年8月14日 — Consider the material and shape of the ball mill liner, wear resistance, impact resistance, etc, and choose the appropriate liner of the original ball mill to replace it Xinhai mining experts suggest that new ball mill liners can be ordered from the original manufacturer 22015年8月8日 — Batch mills Mills which receive a discrete quantity of charge which is milled and then discharged The process is then repeated Continuous mills A mill which can accept a continuous flow of feedstock and hence can operate on a continuous basis Both batch and continuous mills have their relative merits Peripheral and trunnion dischargeMineral processing milling2015年8月24日 — The Anglo American phosphate mine is located in the Brazilian state of Goi#225;s and possesses one of Brazil’s most important phosphate rock deposits, with the site being the country’s second largest producer of phosphate rock concentrate Despite the site having been in operation since 1979, the mining team only started using explosives OneMine Fragmentation Optimisation – Adopting Mine to Mill 2021年1月12日 — Blasting for Mine to Mill Optimisation by Andrew Scott Scott Mine Consulting Services Pty Limited Dr Sarma Kanchibotla Julius Kruttschnitt Mineral Research Centre coarse material is fed there will be insufficient grinding media to grind the feedstock to the required size This size is dictated by the size of the apertures inBlasting for Mine to Mill Optimisation SMC Testing

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator

AG/SAG mills are normally used to grind runoffmine ore or primary crusher product Wet grinding in an AG/SAG mill is accomplished in a slurry of 50 to 80 percent solids 2D and 3D simulations of particles in a SAG Mill red=fastest, blue=slowest moving particles4 天之前 — Type of Mill Typical Lower Grind Size P80 µm Power Intensity kW/m3 Ball Mill 75 20 Tower Mill 20 40 UFG Mill 5 280 Two basic types of UFG mills are available, the vertical stirred mill and the horizontal stirred mill Both use rotating stirrers within a stationary mill shell to impart kinetic energy to a fine media charge (usually sand)Microsoft Word Mill Operator's Paper FINALdoc2024年2月12日 — Factor Description; Type of Mill: Manual: Requires handcranking, laborintensive, no power consumption Electric: Uses a motor, more convenient, faster grinding: Grinding Mechanism: Stone Grinding: How to pick the best home grain mill: A buyer's 2023年9月7日 — The United States and the European Union are working on an agreement for new tariffs aimed at excess steel production from China and other countries, Bloomberg News reported on ThursdayUS, EU plan new steel tariffs aimed at China, others MINING

.jpg)

"grind" 和 "mill " 和有什么不一样? HiNative

2023年11月7日 — grindgrind the action of grinding something into a smaller pieces mill a building where they grind flour or other grains OR can mean to grind "we grind the flour at the mill" "we milled wheat into flour" 的同义词2023年7月13日 — for commodities continuing to increase, mining companies require new ways to costeffectively liberate minerals and maximize recovery levels The Outotec HIGmill® is an advanced and energyefficient fine and ultrafine grinding solution that relies on proven technology The mill takes advantage of gravitational forces andOUTOTEC HIGMILL – ENERGYEFFICIENT HIGH Home Grain Mills that Use Impact Mechanisms These types of mills use a series of rotating metal fins that move very fastWhen the wheat passes through them, the fast impact breaks up the wheat into smaller pieces, eventually turning it into flour Impact milling is a relatively new method of milling that came about much later, and works differently to traditional Best Grain Mill for Bread Flour: Full Buyers Guide2021年10月6日 — What can I grind in a grain mill? Amaranth This is a great source of fibre, and also minerals like iron, magnesium, manganese, phosphorus, and zinc It is a popular choice of grain for making Crackers, and pastries like Unleavened bread, especially in the Middle East You can grind this in a grain mill and it will give you the desired textureCan You Grind Coffee In A Grain Mill? grindily

HS Code Tariff Classification of Grinding balls

2024年1月4日 — Use Flexport's free tool to find the tariff code to correctly classify your goods for customs HS Code Tariff Classification of Grinding balls and similar articles for mills Skip to content2020年1月30日 — The first of these levers, including Mining Method Selection, Process Route Selection and Scale of Operation levers are discussed in Mine Planning 1 – StrategyMine planning: From strategy to operation to optimization2023年9月21日 — mills equalling the ball mill efficiency could lie in the region of F80 = 3 to 4mm The vertical gravity induced mill has a recommended efficiency factor to 080 (ie 20% energy benefit) or higher when feeding the Vertimill with coarse feed F80 = 26mm (Hounde 2019) Ballantyne (2021) determined that the scaleup couldRECENT DEVELOPMENTS IN COARSE GRINDING USING 2024年7月24日 — Plant Mining company Year Installed, Mill Diameter, m Mill Length, m EPCLonmin2002 4250 K4Lonmin2002 4750 Karee Mixed Lonmin 1990 52 59 Karee UG2 Lonmin 1999 47 50 RoM BALL MILLS A COMPARISON WITH AG/SAG

Effect of Water Density on Grinding Mill

2015年7月29日 — The bad side of the water is that it takes up space The more water that is added, the faster the ore will go through the mill This means the time it has to be ground will be reduced and a poor grind will 2020年6月23日 — Grinding mills, including SAG (semiautogenous grinding) mills and ball mills, consume approximately 6070% of the total energy cost of the entire mining operation The mills are installed with large motors, Converting a ball mill from overflow to grate 2020年8月12日 — The elastic limit of the mill shell material is typically at least 6 times the mill operating stress In fact, when a dropped charge breaks flanges, we know that the impact loads have exceeded the Keeping an eye out for grinding mill dropped charge and MINING2022年6月29日 — AG Mill Blasting CWI RWI Rod Mill Pilotscale HPGR SPT Labscale HPGR HPGR AG Pilot Plant SPI® SAGDesign JKRBT® IsaMill™ Stirred Media Detritor Vertimill® BWI Secondary Ball Mill Primary Ball Mill Sign Plot Grey : Industrial/Production Blue : Testing Size K 80 (mm) 0001 001 01 1 10 100 1,000SAG Mill Testing Test Procedures to Characterize Ore

Trump traveling to Illinois steel mill amid tariffs dispute

2018年7月23日 — President Donald Trump will be visiting an Illinois steel mill that is boosting production as he faces opposition to his imposition of tariffs in international trade disputes Trump traveling to Illinois steel mill amid tariffs dispute Updated [hour]:[minute] [AMPM] [timezone], [monthFull] [day], [year] Share Share Copy Link copied 2014年2月1日 — Energy costs related to comminution are closely related to head grade, grind size and mineral type, both of which have in recent times shown common trends across mining projects globally The Mine and Mill cost distributions were similar, centred at 40–50% (relative cost) with similar spreadsMine operating costs and the potential impacts of energy and 2016年2月26日 — The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and Hammer Mill Crusher Grinder 911Metallurgist2017年9月1日 — The first stirred mill was installed in the platinum industry in 2002, and by the year 2010, forty stirred mills had been installed at various platinum operations in South Africa, and these led to a step change in flotation recoveries (Rule, 2011, Rule, 2010)Over the last decade, approximately 200 Automated Scanning Electron Microscopy (Auto Fine grinding: How mill type affects particle shape characteristics

grind or mill WordReference Forums

2011年9月12日 — In English we usually grind coffee but mill wheat (and other grains) As far as I know they are synonyms unless, perhaps, milling produces a finergrained endproduct "patio de molienda" maybe millyard or millfloor? What is the patio de molienda used for? L lloyds Senior Member Ciudad de Buenos AiresHIGmill high intensity grinding mill is an advanced and energyefficient fine and ultrafine grinding solution that relies on proven technology Mining Supporting your operations, from plant design expertise to equipment, HIGmill high intensity grinding mill Metso2013年7月31日 — Reference: Wills, BA, 1988, “A Rapid Method for Measurement of Fineness of Grind”, Minerals Engineering, Vol1, No 1, pp 8184 Here is an Excel produced Table of a 32 SG rock on which you Quick Grind Check How to Quickly Estimate 2024年9月22日 — Grinding mills are crucial equipment in the mining and mineral processing industry, used primarily for the reduction of ore and mineral particles The proper functioning of grinding mills is vital for the efficiency of the overall processi The ore is fed into the mill and as the cylinder rotates, the balls crush and grind the ore, causing Understanding the operation of grinding mills in the mining

Towards waterless operations from mine to mill ScienceDirect

2022年9月1日 — Moreover, in most cases, waste rock is harder and, consequently, more difficult to grind than the ore which is often found in the weaker areas of the rock The harder the rock, the longer the grinding time and the lower the mill throughput Further, hard rock results in overgrinding the ore and higher energy consumption Efficient handling 2017年10月26日 — a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this factor into account As well, mills with different length to diameter ratios for a given power rating will yield different material Factors Affecting Ball Mill Grinding Efficiency 911Metallurgist6 天之前 — DOVE Ball Mills are highly efficient grinding mills designed to grind and blend bulk material ranging from soft, fibrous to hard and brittle material DOVE Ball mill, also known as Grinding mill, Mining mill, Pebble mill, Ball Pebble mill, is an important machinery in the mining and various other industries, which would require grinding Ball Mill Ball Mills Wet Dry Grinding DOVE2015年8月6日 — Before doing multiple laboratory flotation bench tests in which you need P80 grind controlled or predicted, you need to build a Grind Calibration curve following this short procedure You will consistently add sufficient water to the mill to achieve a pulp density of 67% solids (Example: 1 kg solids + 05 kg water or 2 kg solids + 1 kg water)Grind Calibration Curve Laboratory Test 911Metallurgist

.jpg)

Milling Molycop

We also produce a range of mill liner bolts and specialised fasteners to the highest technical specifications Molycop is dedicated to providing the latest in technological advances to our customers Our consumable products coupled with our specialised range of milling instrumentation and real time analytics will deliver improved outcomes for Grinding Mill worth $7,936,222 under Sub Chapter 8479 have been imported; Average import price for grinding mill under Sub Chapter 8479 was $12237 Please use filters at the bottom of the page to view and select unit type [FOC] GRIND LID [SPARE PARTS TO BE USED IN DEVELOPMENT OFHUMMER MILL MACHINERY][SAMPLE] Angola: Grinding Mill Imports Under Sub Chapter 8479 ZaubaGrinding Mills: Ball Mill Rod Mill Design PartsCommon types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed herePhotographs of a glass ended laboratory Grinding Mills 911Metallurgist