Cement Production Process Raw Material

Raw materials for cement manufacturing

Main sources of alkalies are raw materials and coal Sulfur (SO3): Sulphates may be present in clinker up to about 3% Sulphur in raw materials increases SOx emission and cause Manufacturing of cement involves various raw materials and processes Each process is explained chemical reactions for manufacture of Portland Cement Cement is a greenish grey colored powder, made of calcined Manufacture of Cement Materials and 2024年9月24日 — There are six main stages of the cement manufacturing process Stage 1: Raw Material Extraction/Quarry The raw cement ingredients needed for cement How Cement is Made Cement Manufacturing Process6 天之前 — Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the Cement Extraction, Processing, Manufacturing

The Cement Plant Operations Handbook International

2019年4月30日 — Providing a comprehensive guide to the entire cement production process from raw material extraction to the finished product, the industry’s favourite technical Cement manufacturers quarry raw materials including limestone, clay, and sand They use fewer resources and contribute to a circular economy by adding raw substances called alternative raw materials, including fly ash, How Cement is Made Portland Cement 2023年12月20日 — Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering The Cement Manufacturing Process Thermo 2 天之前 — The most important raw materials for making cement are limestone, clay, and marl These are extracted from quarries by blasting or by ripping using heavy machineryHow Cement Is Made Heidelberg Materials

.jpg)

A practical guide to improving cement manufacturing

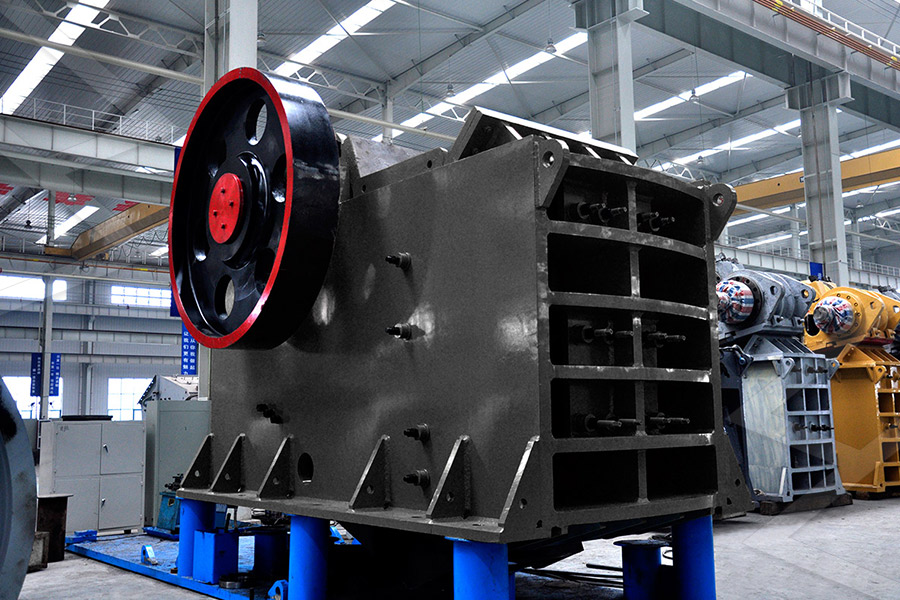

2024年5月22日 — The cement production process 1 The Quarry: The cement production process begins with the extraction of limestone and clay from the quarry 2 Crusher and 2018年8月28日 — Cement Manufacturing Process Cement is the basic ingredient of construction and the most widely used construction material It is a very critical ingredient, because only cement has the ability of Cement Manufacturing Process The Cement quality is an essential parameter to consider when alternative raw materials are introduced into the manufacturing process The typical composition of clinker, which must be achieved in the mixture of natural raw materials and fuel ash, is shown in Table 1 [2] Cement Production an overview ScienceDirect TopicsIf you happen to be a geologist, the raw materials quarry is probably the most interesting part of a cement works, maybe unless you view the clinkering process as igneous rocks in the making The most common Cement manufacturing raw materials

Cement Manufacturing Process Engineering Intro

2012年8月30日 — Cement Manufacturing Process Phase 1: Raw Material Extraction Cement uses raw materials that cover calcium, silicon, iron and aluminum Such raw materials are limestone, clay and sand Limestone is for calcium It is combined with much smaller proportions of sand and clay Sand clay fulfill the need of silicon, iron and aluminum2 天之前 — The crushed material is transported into the raw material storage of the cement plant by conveyorbelts, cableways or railways and also in exceptional cases with trucks This is why the whole production process is monitored and controlled from a central control room where all the data from the plant and the laboratory come together Highly How Cement Is Made Heidelberg Materials2019年4月23日 — Introduction Portland cement underpins modern global development As such, it is the most abundantly produced material in the world (Deolalkar Citation 2016)The world has an abundance of the primary raw materials for cement manufacturing and, compared to other construction materials, cement’s cost is low and it has good durability An overview of alternative raw materials used in cement and 2024年1月15日 — Cement making process – Raw materials, clinker, cement Cement Manufacturing Process Cement Manufacturing Process Cement Manufacturing Process CaO SiO 2 Al 2 O 3 Fe 2 O 3 MgO Loss Limestone (chalk) 520 57 08 03 04 404 Highsilica limestone 336 368 18 06 05 264Cement Manufacturing cdnwordpresswebspeccloud

.jpg)

From raw materials to cement

2022年2月12日 — The most important raw materials for making cement are limestone, clay and marl These are extracted from quarries by blasting or by ripping using heavy machinery Wheel loaders and dumper trucks production process is monitored and controlled from a central control room where all the data from the plant and2023年1月15日 — The manufacturing of cement involves two processes known as the wet process and the dry process, depending upon whether the mixing and grinding of raw materials is done in a wet or dry state Cement Manufacturing PlantPortland Cement: Raw Materials, Manufacturing, Types and 2023年10月13日 — The production process of cement releases large amounts of CO2, mainly due to the hightemperature firing of raw materials, such as limestone and clay, but also due to energy and resource Global database of cement production assets and upstream 2021年3月3日 — Cement is produced by a hightemperature (about 1500 °C) reaction in a rotary kiln of carefully proportioned and blended ratios of lime (CaO), silica (SiO 2), alumina (Al 2 O 3), and iron oxide (Fe 2 O 3)The production of cement is a chemical process requiring an accurate blend of the previously cited four key organic oxides and the Cement SpringerLink

.jpg)

Manufacturing of Portland Cement – Process

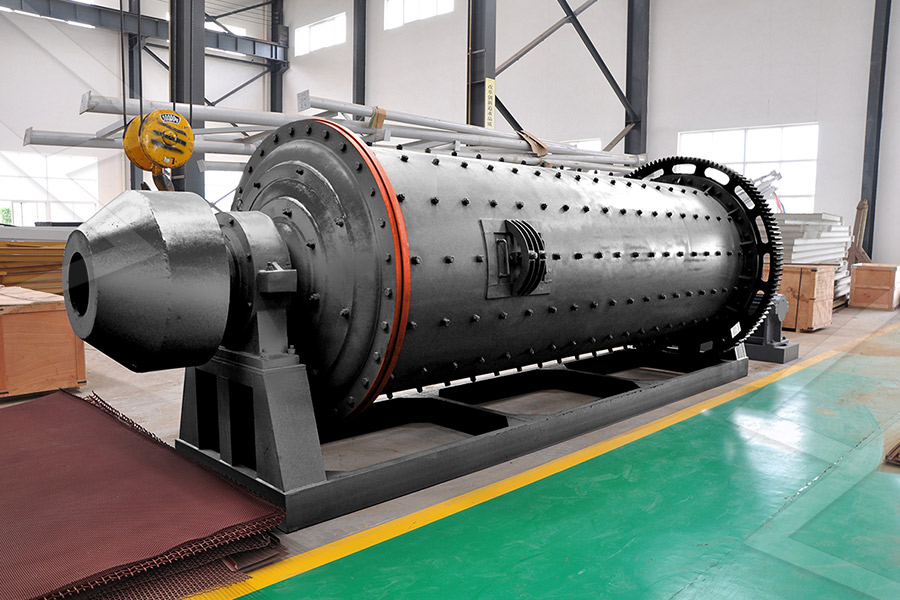

3 天之前 — The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and 2024年5月22日 — The cement production process 1 The Quarry: The cement production process begins with the extraction of limestone and clay from the quarry 2 Crusher and PreBlending: The material is then crushed to reduce particle sizes and blended to reduce variability in composition 3 Raw Mill and Kiln: Raw materials and additives areA practical guide to improving cement manufacturing 6 天之前 — Cements may be used alone (ie, “neat,” as grouting materials), but the normal use is in mortar and concrete in which the cement is mixed with inert material known as aggregateMortar is cement mixed with sand or crushed stone that must be less than approximately 5 mm (02 inch) in size Concrete is a mixture of cement, sand or other Cement Definition, Composition, Manufacture, History,2020年9月22日 — Much of the processrelated water is consumed during the quarrying, crushing and washing of raw materials used in the production of cement and concrete; for example, water is used for dust Environmental impacts and decarbonization strategies in the cement

Cement Production Demystified: StepbyStep Process and

2024年1月18日 — Cement production process overview What are the different steps to manufacture cement ? The raw materials used in this process typically include limestone, clay, and sands while other minerals such as iron ore and shale can also be used As explained above these materials must be crushed and ground into a fine powder before The principal raw materials for cement manufacturing are: Limestone; Silica and alumina from basalt , shale or sand; Iron from iron ore or steel mill scale Sand stone; Pumice (volcanic ash for Portland Pozzolana cement ) Gypsum General Properties of Raw Material Sources Limestone; The basic raw material of the cement production is limestoneCement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT2024年6月1日 — Cement production is a complex and essential process that involves several stages and impacts various aspects of the construction industry and the environment The first step in cement production is the extraction of raw materials, primarily limestone, clay and shale [34] These materials are typically obtained from quarries or mines, where Decarbonising cement and concrete production: Strategies, Take a look at our interactive animation of the cement production process to learn how cement is made by us at CEMEX Products Services Solutions Tools Support in which huge rotary kilns come into play Inside, at 1400 degrees C, the raw material is transformed into clinker: small, dark gray nodules 34 centimetres in diameter 9 Cement Production: How Cement Is Manufactured CEMEX UK

Chapter 4 Cement Manufacturing and Process Control

2019年8月26日 — sheet of cement manufacturing is given in Fig 41 Kiln feed is subjected to successive physical and chemical reactions as its temperature rises gradually as shown in Table 41 42 Raw Material The major raw materials used as a source of CaO for cement manufacturing are limestone, chalk, marl, etc2022年11月17日 — The cement manufacturing process mainly includes four steps: resource extraction, raw material preparation, clinker calcination, cement grinding 17,18, and fossil fuel burning 19Modernizing cement manufacturing in China leads to 3 天之前 — The other raw materials that are used in cement manufacturing, called additives, are high purity limestone, sand and iron ore The high purity limestone is crushed in a lone in jaw crusher and then crushed more in a Manufacturing process Lafarge2016年1月1日 — The previous research focused on the use of oilwell cutting material beside the raw materials in the cement production process, whereas till the writing of the current research few published Feasibility Study on Spent Pot Lining (SPL) as

.jpg)

How Concrete Is Made Cemex USA

How Concrete is Made: Water This is the mix’s vital fluid, which sets of a chemical reaction when it comes into contact with the cement How Concrete is Made: Cement No other material rivals cement’s importance in the mix; it’s the ingredient that gives concrete its resistance How Concrete is Made: Concrete mixing1971年8月17日 — 116 Portland Cement Manufacturing 1161 Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites More than 30 raw materials are known to be used in the manufacture of 116 Portland Cement Manufacturing US EPA2023年10月16日 — World cement production is about 43 billion tons per year 1, with an average consumption of raw materials of about 16 tonnes for each tonne of cement manufactured 2Valorisation of waste or by Thermodynamic modelling of cements clinkering process as Since blasting is not required for quarrying of chalk, and the crushing process can also be omitted, this kind of raw material considerably lowers the cement production costs In some deposits the calcium carbonate content of chalk amounts to 9899 0/o, with small admixtures of Si02, Al203, and MgC03Raw materials used for Cement Production INFINITY FOR CEMENT EQUIPMENT

Cement Formula, Properties Application Material

2024年9月14日 — The manufacturing process of cement involves numerous steps, starting from the mining of raw materials to the packaging of the final product The primary steps include quarrying, raw material preparation, clinker production, cement grinding, and packaging Raw Material Preparation: The extracted materials are crushed and 2015年12月9日 — Raw materials are used to produce the main cement elements (Mohsen, 2015) • Quarry The process of obtaining raw materials for cement manufacturing involves mining and quarrying natural materials (PDF) Cement Manufacturing ResearchGate2016年1月20日 — In the surveyed cement plant, three balances are established between input and output material in the raw mill, clinker production, and cement grinding system 248 t, 469 t, and 341 t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages; waste gases Analysis of material flow and consumption in cement production process 2017年12月5日 — Methods of Manufacturing Process of Cement At present Portland Cement is manufactured by two processes, Dry Process, and Wet Process The main difference between these two methods of Cement Manufacturing Process: What is Cement

Cement Manufacturing Process Chemical

2020年9月26日 — Cement Manufacturing Process Cement Manufacturing Process Cement Manufacturing Process Cement is a material which is used to bind other materials together Binding means it has an effect of 2023年2月1日 — Raw material blending is an important process affecting cement quality The aim of this process is to mix a variety of materials such as limestone, shale (clay), sandstone and iron to produce CEMENT RAW MATERIALS BLENDING PROCESS 2024年5月1日 — Cement production involves a complex process wherein raw materials like limestone, clay, and other substances are heated to high temperatures to produce clinker, the main component of cement This process is energyintensive and primarily relies on fossil fuels, leading to substantial CO 2 emissionsRoadmap to a netzero carbon cement sector: Strategies, The Manufacturing Process The manufacture of concrete is fairly simple First, the cement (usually Portland cement) is prepared At the cement production factory, the proportions of the various raw materials that go into cement must be checked to achieve a consistent kiln feed, and samples of the mix are frequently examined using Xray How concrete is made material, manufacture, making, how

Cement Manufacturing—Technology, Practice, and

2021年11月17日 — A cement manufacturing process is well suited for coprocessing of wastes from different sources Wastes need to be converted into alternative fuels and raw materials (AFRs) through the preprocessing operation and then utilized to substitute fossil fuels and raw materials used in the cement process2021年11月16日 — 76 4 Cement Manufacturing—Technology, Practice, and Development Fig 42 Modern dry process cement production process 424 Manufacturing of Cement Clinker The prepared raw material is called the “kiln feed” and is fed to the kiln In the kiln, this kiln feed is subjected to a thermal treatment process which consists ofCement Manufacturing—Technology, Practice, and 2023年12月7日 — Throughout the cementmaking process, these raw materials undergo chemical transformations that ultimately result in the main ingredients of cement For example, shale contains silica and alumina After passing quality control, this mixture, now called raw meal, is ready to move on to the next step in the cement production process How Is Cement Made? StepbyStep Guide BigRentz2019年11月1日 — As the most fountainhead process of the whole cement production process, the raw material blending process has a decisive influence on the quality of the final product [1] Different chemical compositions of oxides in raw meal will produce different products with a specific strength grade But the chemical compositions of raw material A novel chemical composition estimation model for cement raw material

.jpg)

What is the Manufacturing Process of Portland Cement?

The manufacturing process of Portland cement is a sophisticated and multistep procedure that transforms raw materials into a vital construction material Many people believe it’s a simple process, but in reality, it involves several key 2018年8月28日 — Cement Manufacturing Process Cement is the basic ingredient of construction and the most widely used construction material It is a very critical ingredient, because only cement has the ability of Cement Manufacturing Process The Cement quality is an essential parameter to consider when alternative raw materials are introduced into the manufacturing process The typical composition of clinker, which must be achieved in the mixture of natural raw materials and fuel ash, is shown in Table 1 [2] Cement Production an overview ScienceDirect TopicsIf you happen to be a geologist, the raw materials quarry is probably the most interesting part of a cement works, maybe unless you view the clinkering process as igneous rocks in the making The most common Cement manufacturing raw materials

Cement Manufacturing Process Engineering Intro

2012年8月30日 — Cement Manufacturing Process Phase 1: Raw Material Extraction Cement uses raw materials that cover calcium, silicon, iron and aluminum Such raw materials are limestone, clay and sand Limestone is for calcium It is combined with much smaller proportions of sand and clay Sand clay fulfill the need of silicon, iron and aluminum2 天之前 — The crushed material is transported into the raw material storage of the cement plant by conveyorbelts, cableways or railways and also in exceptional cases with trucks This is why the whole production process is monitored and controlled from a central control room where all the data from the plant and the laboratory come together Highly How Cement Is Made Heidelberg Materials2019年4月23日 — Introduction Portland cement underpins modern global development As such, it is the most abundantly produced material in the world (Deolalkar Citation 2016)The world has an abundance of the primary raw materials for cement manufacturing and, compared to other construction materials, cement’s cost is low and it has good durability An overview of alternative raw materials used in cement and 2024年1月15日 — Cement making process – Raw materials, clinker, cement Cement Manufacturing Process Cement Manufacturing Process Cement Manufacturing Process CaO SiO 2 Al 2 O 3 Fe 2 O 3 MgO Loss Limestone (chalk) 520 57 08 03 04 404 Highsilica limestone 336 368 18 06 05 264Cement Manufacturing cdnwordpresswebspeccloud

.jpg)

From raw materials to cement

2022年2月12日 — The most important raw materials for making cement are limestone, clay and marl These are extracted from quarries by blasting or by ripping using heavy machinery Wheel loaders and dumper trucks production process is monitored and controlled from a central control room where all the data from the plant and2023年1月15日 — The manufacturing of cement involves two processes known as the wet process and the dry process, depending upon whether the mixing and grinding of raw materials is done in a wet or dry state Cement Manufacturing PlantPortland Cement: Raw Materials, Manufacturing, Types and 2023年10月13日 — The production process of cement releases large amounts of CO2, mainly due to the hightemperature firing of raw materials, such as limestone and clay, but also due to energy and resource Global database of cement production assets and upstream